Incoming material shall be inspected according to the quality plan and after conformity it has to be received by store. In the case of non conformity the material shall be returned to supplier without any delay. Different manufacturing stages has identified where inspection/testing is required and shall be done as per the drawings/flow charts. All the inspection and testing will be done at planned stage. And if any rework or non – conforming product arises shall be recorded and rest will be treated as marked QA/QC passed.

Final product inspection is carried out as per quality plan/drawing/flow charts. Evidence of conformity find, test report will be prepared. No product delivery shall be made until it conforms the specified requirement production manager is authorized to sign on delivery paper for product conformity. All the non-conformities arise during inspection at any stage will be handled as per procedure of “control of non conforming product”. The processes are identified with their monitoring systems. Process performance shall be monitored regularly by production manager. All the record of monitoring will be maintained. Monitoring data shall be discussed in quality in charge any change needed shall be incorporated in processes.

Since the final inspection is done, any defects observed during the final inspection are considered as the non-conformity and recorded in the final inspection report/register. If the defects are minor, the identified product is reworked and offered again for inspection.

If the defects are major and product is rejected.

Then the non-conformity material are removed from the working place and then offered again for review for its use, release or acceptance under concession the authority lies with quality check in charge only.

All potential non-conformity identified out of recorded non-conformities.

Root case analysis will be done with the help of statistical technique or past experience. Production manager will be evaluate the need for action to prevent recurrence of non-conformities. Determination of appropriate action and implementation plan. Implementation of action needed as per plan. Follow up for results, Review of follow up, Reporting in management review meeting. Record of preventive action and its implementation will be maintained.

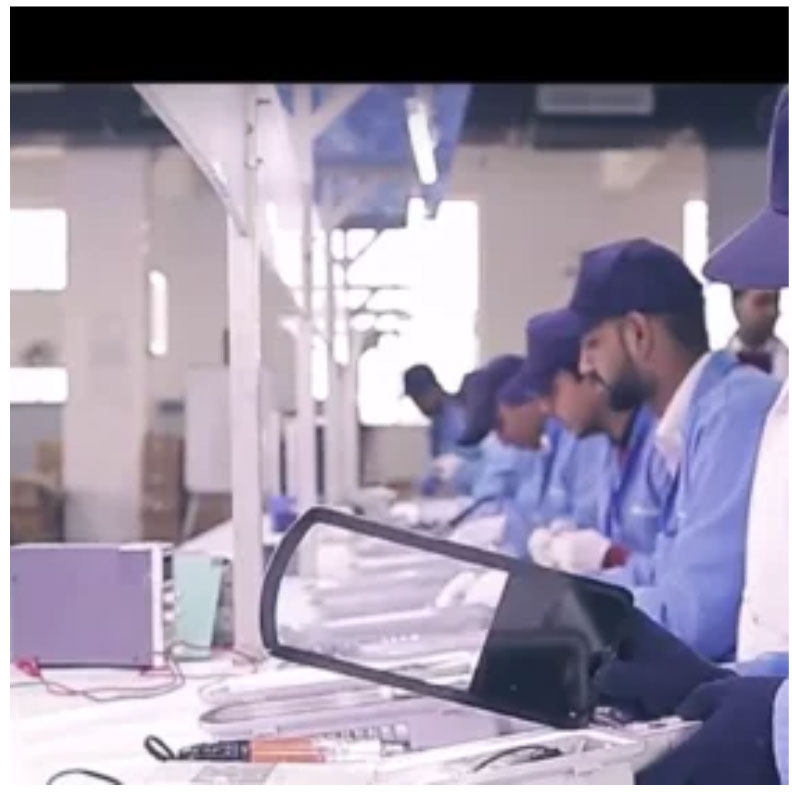

We have built up our production facilities for serving markets all over India. Our production set up includes Manufacturing of LED –Lights , Power Backup-products, Solar Products Our manufacturing facility is systematically planned and built to modern construction standards.

Equipped with sophisticated assembly lines and are backed by a completely integrated in-house R&D Centre. Executes multiple functions in one cycle at high speed ensures full safety of sophisticated equipment Well-trained multi-skilled workforce assemble all the components on assembly lines

Productivity improvement is a critical area of focus in various operations

Lighting distribution measurement of all kinds of

with high accuracy; Lighting distribution measurement of all kinds of light sources including LED, CFL, FL, HID, energy saving lamps

A solar simulator is a device that provides illumination approximating natural sunlight. The purpose of the solar simulator is to provide a controllable indoor test facility under laboratory conditions, used for the testing of Solar panels.

ITECH high-speed high performance photovoltaic/solar simulation power supply can help users to complete the solar array output simulation under different shadow modes, test and track real-time maximum power and performance test of the PV array. Providing various Module for the user to choose according to a different supplier, users can also build their own PV module.

User can define irradiation and temperature parameters of shadow, cell string set, parallel quantity and dynamic shielding the moving direction of the cloud, initialization time, running time and the time interval of cloud moving.